Advancements towards (bio)refining tomorrow

Empowering bioeconomy growth through advanced biorefineries

A key driver to satisfy the energy and material demands of society sustainably is the implementation of the bioeconomy, which relies on renewable bio-based resources for the production of materials and energy.

The EU's projected demand for bio-based chemicals and materials, under a high-growth scenario, is expected to reach approximately 16 million tonnes per year (Mtpa), with a yearly growth rate of around 9.9% until 2030.1 Notably, this projection excludes bioenergy, biofuel, and traditional bio-based products such as paper and board.

The upswing in demand is reflected in increased investments in one of the cornerstones of the bioeconomy: biorefineries. Recently, EcoCeres, an Asia-based advanced biorefinery company, received a significant equity investment from Bain Capital.

The backbone of the industry

Biomass, obviously, is nothing new. It has been around since before humans, and the utilization of biomass for energy is nearly as old as humanity itself.

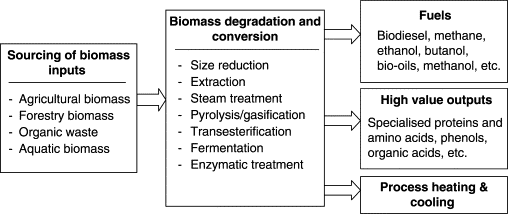

Similarly, biorefineries have existed for a significant period. A biorefinery is generally defined as the sustainable processing of biomass into a spectrum of marketable products and energy. This encompasses various concepts, including traditional biomass processing facilities like conventional biofuels plants and pulp mills.

Earlier generation biorefinery concepts are simple, using one feedstock (e.g., vegetable oil) and producing two or three products (e.g., biodiesel, animal feed, glycerine) with currently available commercial technologies. As fuel products are usually low-valued regardless of the biomass feedstock, earlier generation biorefineries have a proven track record of significant economic hurdles, especially in conjunction with falling oil prices. This became evident during the Clean Tech Bubble 1.0 days.2

It’s in the name: Advanc(ing)e Biorefinery

Over recent years, the concept of "advanced biorefineries" (also known as “integrated biorefineries” or “biorefinery platforms”) has emerged.3 Advanced biorefineries aim to overcome financial hurdles by integrating various biomass conversion technologies and multiple feedstocks to produce value-added products, biofuels, and bioenergy (thermal or electrical) simultaneously while recycling all waste outputs with little to no discharge.

Figure. An overview of the biorefinery concept from input to output.

Consequently, advanced biorefineries have the potential to perform better economically and energetically than stand-alone biomass-to-fuel facilities.4

(Waste) mounds and (oil) puddles along the way

Currently, several different concepts of newly advanced biorefineries are under development, focusing on feedstocks, conversion processes, platforms, and products.5 However, a common hurdle in the commercialization of biorefineries is their economic viability.6

Economic challenges start from procuring biomass and high upfront development costs and extend to, among other factors, long-term output price stability. As a rule of thumb, the cost-competitiveness of biobased products increases with rising oil prices and decreasing feedstock costs.

Therefore, one of the most discussed and apparent challenges is that biomass resources (land and aquatic crops; agro, forestry, and process residues; and post-consumer residues) have to be sourced efficiently in terms of resources, energy, sustainability, and stability while being cost-efficient.7 The (economic) success of biorefineries is largely dependent on the quality and quantity of available biomass.8 Subsequently, biorefineries are lining up to secure a long-term, nearby, stable supply of secondary biomass. For example, EcoCeres has partnered with a waste management firm backed by the Chinese city of Shenzhen to source feedstock.

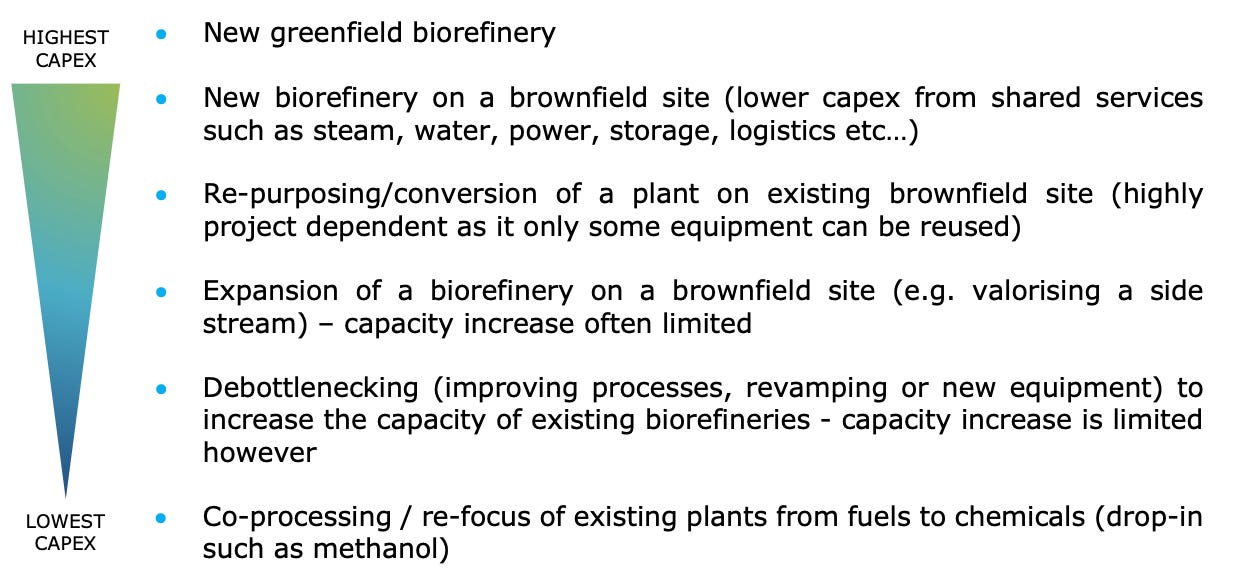

To reduce high upfront costs, the integration of new biorefinery concepts into existing industrial complexes holds an interesting path.9 As advanced biomass conversion plants will require similar plant concepts as today's chemical plants or today's crude oil refining, these prospects are actively explored.

Figure: Investment types to ramp-up bio-based chemical and material production.10

Furthermore, alongside multiple products enabling diverse revenue streams, policy incentives are implemented to enhance long-term output price stability. The EU’s Renewable Energy Directive III (RED III) intends to set a binding combined sub-target of 5.5% for advanced biofuels and renewable fuels of non-biological origin (RFNBOs) in the share of renewable energies supplied to the transport sector by 2030. The US plans to supply sufficient Sustainable Aviation Fuel (SAF) to meet 100% of aviation fuel demand by 2050.

The shift from traditional refinery to advanced biorefinery could help leapfrog significant hurdles in the evolution of the bioeconomy, minimizing waste, optimizing resource use, and reducing reliance on fossil fuels. However, the road ahead is subject to the development of a myriad of interrelated factors, from feedstock sourcing to the integration of innovative concepts to policy incentives, which should be monitored closely.

Deepsense is the expert network for science and technology.

We have bioeconomy experts from leading institutions . Reach out to us to schedule expert calls and materials reviews to get support with technical assessments of your next opportunity.